Cart

Heat Presses 101: Must-Know Facts

Choosing a heat press can be overwhelming with the many options available today. Heat presses come in all shapes, sizes, and colors, each with unique features and designs. From sleek and modern to industrial and functional, it can be hard to decide which one is best suited for your needs. In this blog, we aim to give you must-know heat press facts to help you navigate the various types of heat presses and select one that meets your budget and application requirements

Heat Press Facts: How Does a Heat Press Work?

No matter the size, color, or cost, all heat presses operate on the same basic principles as household appliances like irons and stoves. They feature a heating element, typically connected to mains voltage, which heats up and transfers warmth to an aluminum plate or rubber pad.

The desired temperature is set by the user, and once reached, the heat element turns off. When the temperature falls below a certain threshold, it reheats, repeating the cycle as needed.

Some presses are equipped with features like auto-open functions and digital temperature control, but the core process remains simple: heating an object for a designated time and temperature to achieve a specific transfer result. While most presses have one heated surface, some specialty presses, such as dual-sided T-shirt presses, offer two heated platens for faster, double-sided transfers.

Table of Contents

- Type of Heat Presses

- Heat Press Mechanisms: T-Shirt Presses

- Clamshell Heat Presses

- Swing-Away Heat Presses

- Combination Presses

- Heat Press Construction

- Element Wire

- Types of Heat Elements Used in Heat Presses

- Cold Spots in Heat Presses

- Heat Platen Manufacture (Excludes Mug Presses)

- Types of Elements in Heat Presses

- Manufacturing Process

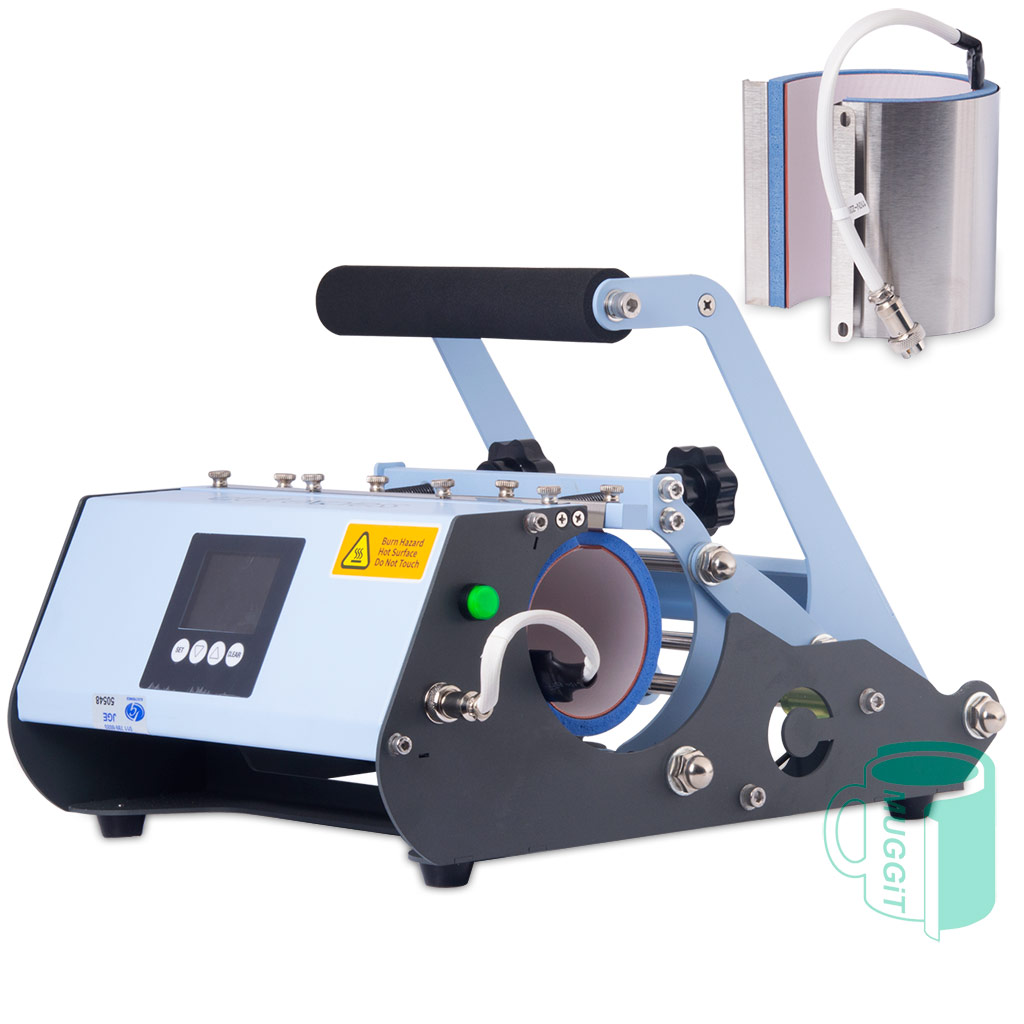

- Mug Presses

- The Temperature Controller in Heat Presses

- Conclusion

- Heat Presses We Sell At JG Electronics

Types of Heat Presses

Today, heat presses are available for a wide variety of applications, including:

- Mug Presses

Made for different sizes and shapes of mugs - Cap Presses

Designed to press onto hats and caps - T-shirt Presses

The most common type, available in several designs - Roller Presses

Used for large fabric rolls before they’re sewn into garments - Specialty Presses

Options for shoes, pens, balls, and other unique items

Heat Press Mechanisms: T-Shirt Presses

Only T-shirt presses offer two distinct main types of mechanisms, each with some variations: clamshell and swing-away. Other types of presses generally come with just one mechanism option. In different regions, these mechanisms may have various names; for instance swing-away presses are known as 'swing' or 'shaking' presses.

If the mechanism appears fragile or has visible, defined welding marks, it’s likely a lower-quality press that isn’t intended for heavy-duty use. And if the mechanism is made of plastic, it’s considered the lowest end in terms of quality.

Clamshell Heat Presses

A clamshell press opens and closes at an angle, similar to a sandwich toaster or waffle maker. While it doesn’t open completely vertical, it usually stops at an angle of about 45 degrees.

Advantages:

- With a simpler mechanism, clamshell presses are the most affordable option.

- They occupy minimal space, making them ideal for shop environments where space is limited.

- These presses can handle nearly all types of transfer processes, even on thicker items.

Disadvantages:

- Because they close at an angle, the back of the press contacts the heat pad before the front. If the engineering is not well-designed (as is often the case with very cheap presses), this can cause uneven pressure from back to front, which is problematic for certain types of transfers.

- Many clamshell presses, due to their mechanism, cannot achieve the same pressure as swing-away presses, which is essential for processes like white toner laser transfers and sublimation on thicker items.

- They’re limited in their ability to press thicker items. Typically, items over 2 cm thick can pose a challenge.

- Users need to exercise caution when adding or removing items to avoid touching the upper heating plate and risking burns. Some manufacturers have addressed this by adding models with a slide-out drawer.

- For models with a slide-out drawer, if the drawer’s runners and moving parts are of poor quality, this can result in pressure inconsistencies.

- They are limited in size, as it’s rare to find clamshell presses larger than 40 x 60 cm.

Swing-Away Heat Presses

In a swing-away press, the heat platen lifts vertically and then swings to the side.

Advantages

- Provides much more even pressure, assuming the heat platen is well-designed. If not, it can be less reliable than a low-cost clamshell.

- Capable of applying higher pressure, provided it has a sturdy mechanism and a well-secured, strong support bar.

- Easily handles thicker items, often over 2 cm.

- Generally built with higher quality mechanisms, depending on the press’s price point.

- Available in larger sizes than clamshell presses.

- Some models come in dual bed versions, allowing one bed to be loaded or unloaded while the other is in use, as well as pneumatic versions for larger units, which reduces labor dependency.

- The size is limited only by practicality and budget; there are models available as large as 120 x 200 cm or more.

Disadvantages

- Requires more space than a clamshell due to the side-swinging mechanism.

- Must never be placed near a window, as swinging too far can lead to broken glass—a common mistake.

- On cheaper models, the mechanism may be prone to breaking, or the support bar may be made of low-grade steel.

- With wear, it can shift out of alignment, causing the platen not to return to the exact center.

- More expensive than a similarly built clamshell press.

- The shaft that raises and lowers the platen requires regular lubrication.

- It’s easier to apply too much pressure, potentially damaging the item or the press itself.

Combination Presses

Combination presses are versatile units that, while primarily designed for pressing T-shirts, also come with a range of add-ons that connect to the main press controller. These attachments allow for pressing on various items like caps, mugs, plates, and even pens.

This type of press is ideal for beginners entering the business, as it provides the flexibility to work on multiple items without the need for separate, specialized presses. However, they aren’t built for handling high-volume production.

These days, both swing-away and clamshell presses often come with additional features such as an auto-release function, which uses an electromagnet to keep the press closed. When the timer reaches zero, the power is cut, releasing the magnet and allowing the press to open.

Other features, like pull-out drawers, are also available. While these add-ons may help differentiate products, they do not significantly improve the quality of the transfer and are often considered more of a marketing gimmick than a practical enhancement.

Heat Press Construction

JG Electronics, with a background in manufacturing heat presses in South Africa during the 1990s, has gained unique insights into heat press construction. This experience has provided them with valuable knowledge of hidden details and nuances that many resellers have yet to uncover.

Element Wire

Heat elements require specialized wire, with Nichrome (a nickel-chromium alloy) being the most commonly used due to its high efficiency, durability, and ability to withstand temperatures up to 1150°C. For higher-end applications, Kanthal and Constantan wires are also used, offering greater stability and longevity.

While some low-end manufacturers may use copper or stainless steel wire to reduce costs, these materials require more energy to reach the same temperatures, ultimately leading to higher electricity costs for the user—offsetting any initial savings from purchasing the cheaper product.

Types of Heat Elements Used in Heat Presses

Heat presses utilize various types of heat elements, each designed for specific applications:

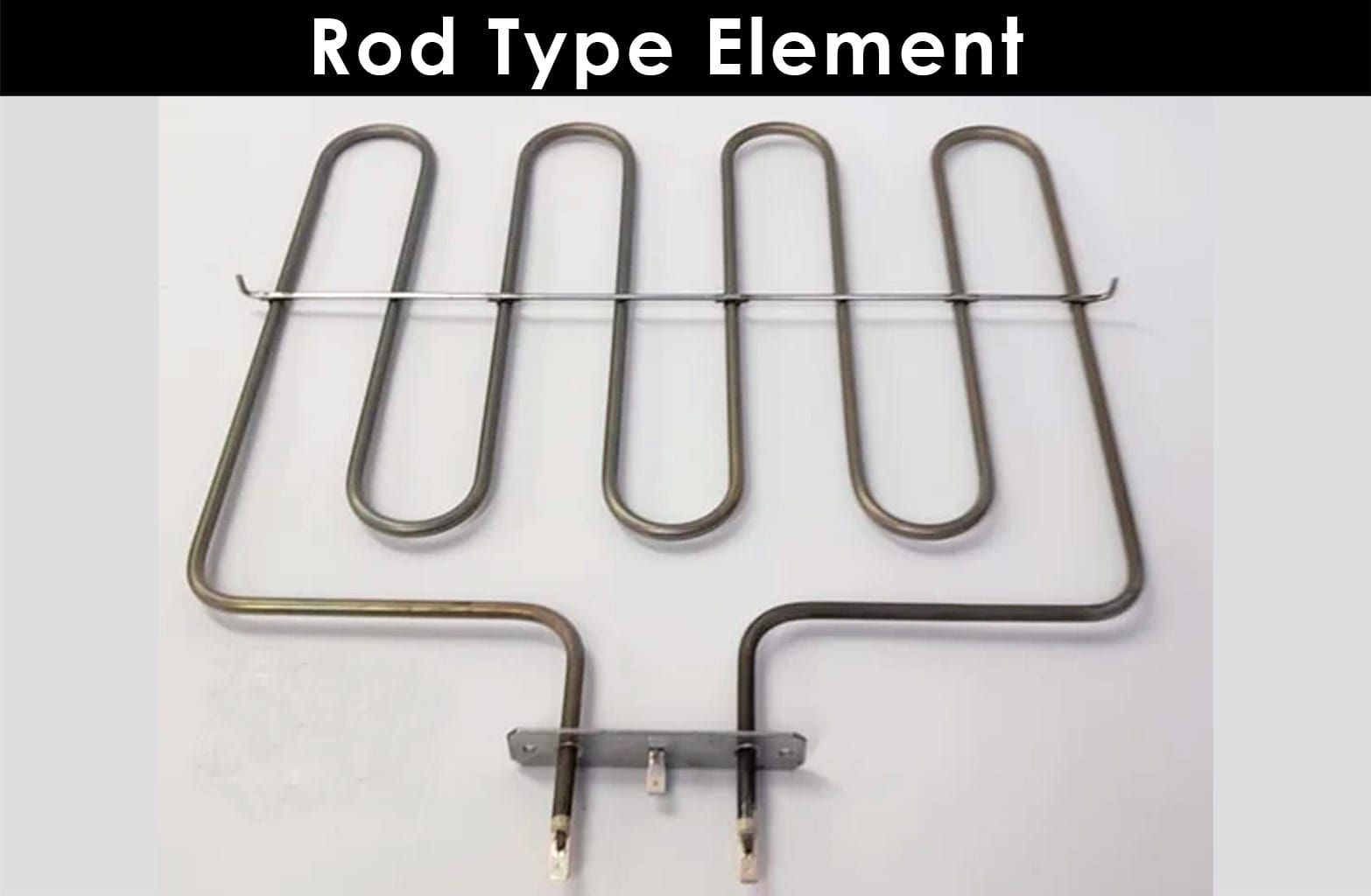

- Grill-Style Elements:

Resembling the heating element in your home oven, these are the most common in T-shirt and flat presses. - Flat Mica Sandwich Elements:

Nichrome flat ribbon wire is wound around a mica core and sandwiched between two mica sheets. These elements are highly efficient and durable but can be up to 10 times more expensive than those from the Far East. - Cylindrical Cartridge Heaters:

Used in cap presses and some specialty or large T-shirt presses, these cylindrical elements are versatile. - Flexible Silicone Heat Pads:

Typically sourced from specialist manufacturers, these pads come in two types:- Wire Wound: The element wire is woven onto a fiberglass core, vulcanized onto a silicone sheet, with a temperature sensor added before a covering silicone sheet is vulcanized to the exposed side. These are the strongest heat pads.

- Etched Foil: Instead of wires, the element is etched out of the material, similar to a printed circuit board. These are ideal for constant heating applications but are more costly to produce, making wire-wound elements more common in mug presses.

Choosing the right heat element is crucial for achieving optimal performance and longevity in your heat press machine.

Cold Spots in Heat Presses

Users sometimes report cold spots on a press, mistakenly thinking the element has burnt out in certain areas. However, a heat element is essentially a long wire, and if it burns out or is cut in one place, the entire element will stop working.

Cold spots can occur due to:

- Element Spacing:

If the element is too widely spaced within the heat platen, it can cause uneven heating.

- Casting Defects:

Imperfections during the casting of the aluminum platen can also lead to cold spots.

Proper maintenance and quality control during manufacturing are essential to prevent these issues and ensure consistent heating performance.

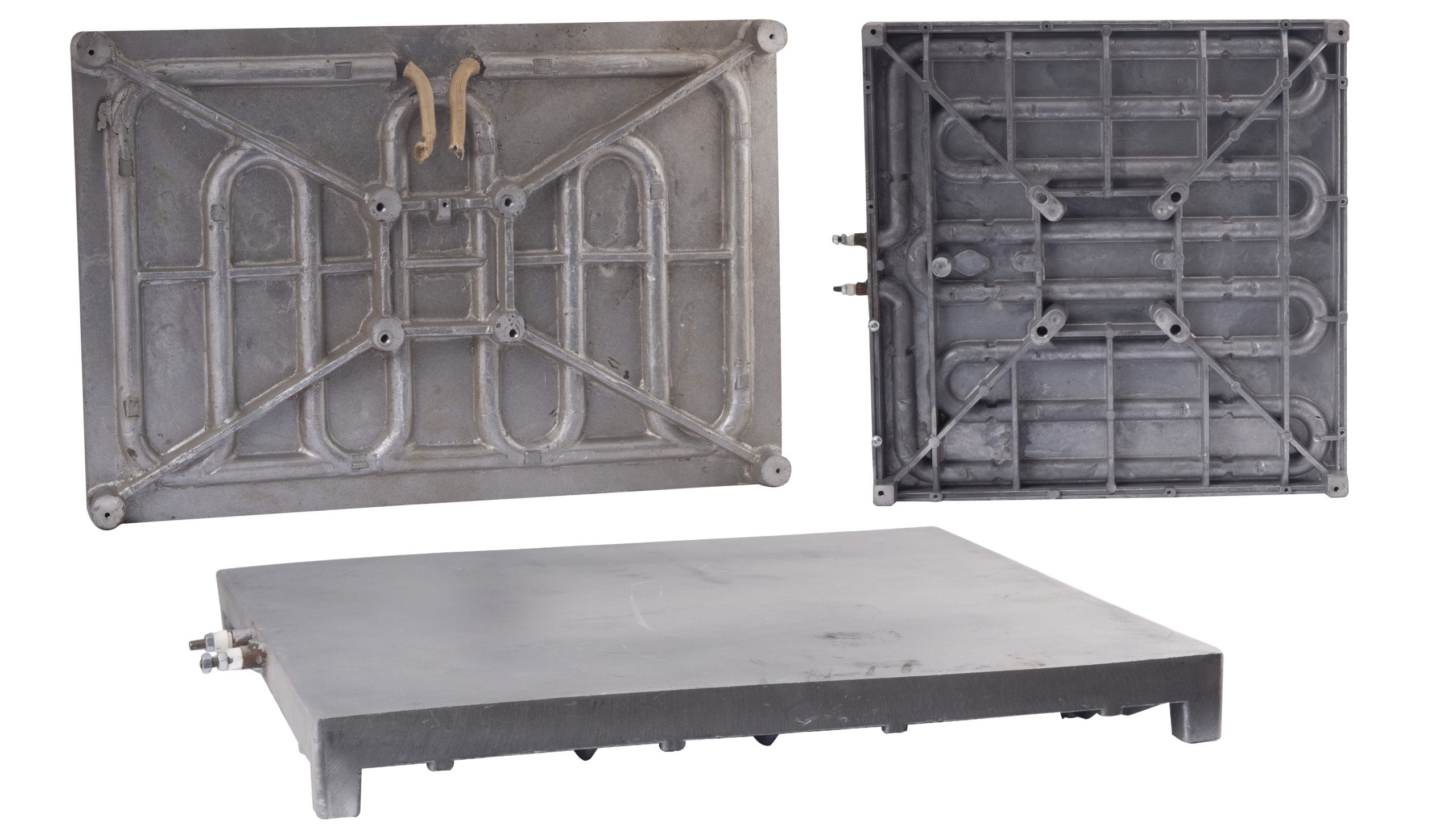

Heat Platen Manufacture (Excludes Mug Presses)

While the methods JG Electronics used 30 years ago are still widely used today, many high-end manufacturers have significantly improved aluminum casting processes. These advancements reduce casting defects, making the finished product more expensive but also increasing heat consistency throughout the platen and dramatically improving the lifespan of the element. Here’s a brief overview:

Heat Platen Overview

The heat platen is the metal block that the element is either:

- Moulded into

Using a sand moulding process - Rested against

In the case of mica sandwich elements - Inserted into

For cap presses and similar curved presses

Material: Aluminum is preferred for its excellent thermal properties and light weight. However, some cheap presses use metalized plastic heat platens, which don’t last long.

Function: The heat platen is heated by the element and transfers heat to the product being imprinted. Thicker aluminum platens are heavier and more expensive but less likely to warp, especially in larger presses. More professional casting processes result in more consistent heat distribution.

Aluminum Trade-Offs

A balance must be struck between thermal conductivity and strength:

- Pure Aluminum:

Softest with the best thermal conductivity. - Harder Aluminum:

Lower thermal conductivity but stronger.

Thicker elements are better for strength. Thin elements use stronger, less heat-conductive aluminum, consuming more electricity.

Types of Elements in Heat Presses

Oven Type Elements

Common in T-shirt and flat presses. Proper casting is crucial; defects can lead to poor heat dissipation and shorter element lifespan.

Example: Look for uneven or missing aluminum on old press elements.

Oven Type Elements

Z or X Shaped Elements

Used in cheaper presses to save costs. These presses often have cold spots due to widely spaced element segments.

Example: Compare presses with oven elements (green tick) and Z/X elements (red crosses).

Z or X Shaped Elements

Manufacturing Process

- Moulding:

The element is laid in the mould, molten aluminum is poured, cooled, cut, machined, and polished. - Mica Sandwich Elements:

Mounted on the aluminum block with bolts, covered with a metal plate, and insulated to prevent upward heat radiation. - Cartridge Elements:

Holes are drilled into thicker aluminum to hold cartridge heaters, ensuring strength and preventing warping.

These improvements and considerations ensure better performance and longevity of heat press machines.

Mug Presses

Most mug presses feature round nichrome heat element wire embedded in a flexible, heat-resistant silicone rubber pad, adhered to a heat-resistant foam moulding, often with Teflon on the side that contacts the item. These elements are common in the market and sometimes include a thin metal mounting plate glued to the back for easy installation.

Applications:

- Cap Presses, Plate Presses, and Small Craft Presses:

Occasionally use the same type of element as mug presses but without the foam moulding to reduce costs. These can be identified by their lack of aluminum and plastic housings.

Important Note:

- Do Not Leave On Unattended:

Presses with this type of element should not be left on without an item being pressed, as the element will quickly fail without something to absorb the heat. The maximum operating temperature for these elements is 230°C.

Advantage:

- Cost-Effective:

Inexpensive to manufacture, allowing for a variety of sizes and shapes to accommodate different mugs.

Disadvantage:

- Heat Absorption:

Without a mug in the press, the element can overheat and fail quickly.

Proper usage and understanding of these elements can help extend the life of your mug press and ensure consistent performance.

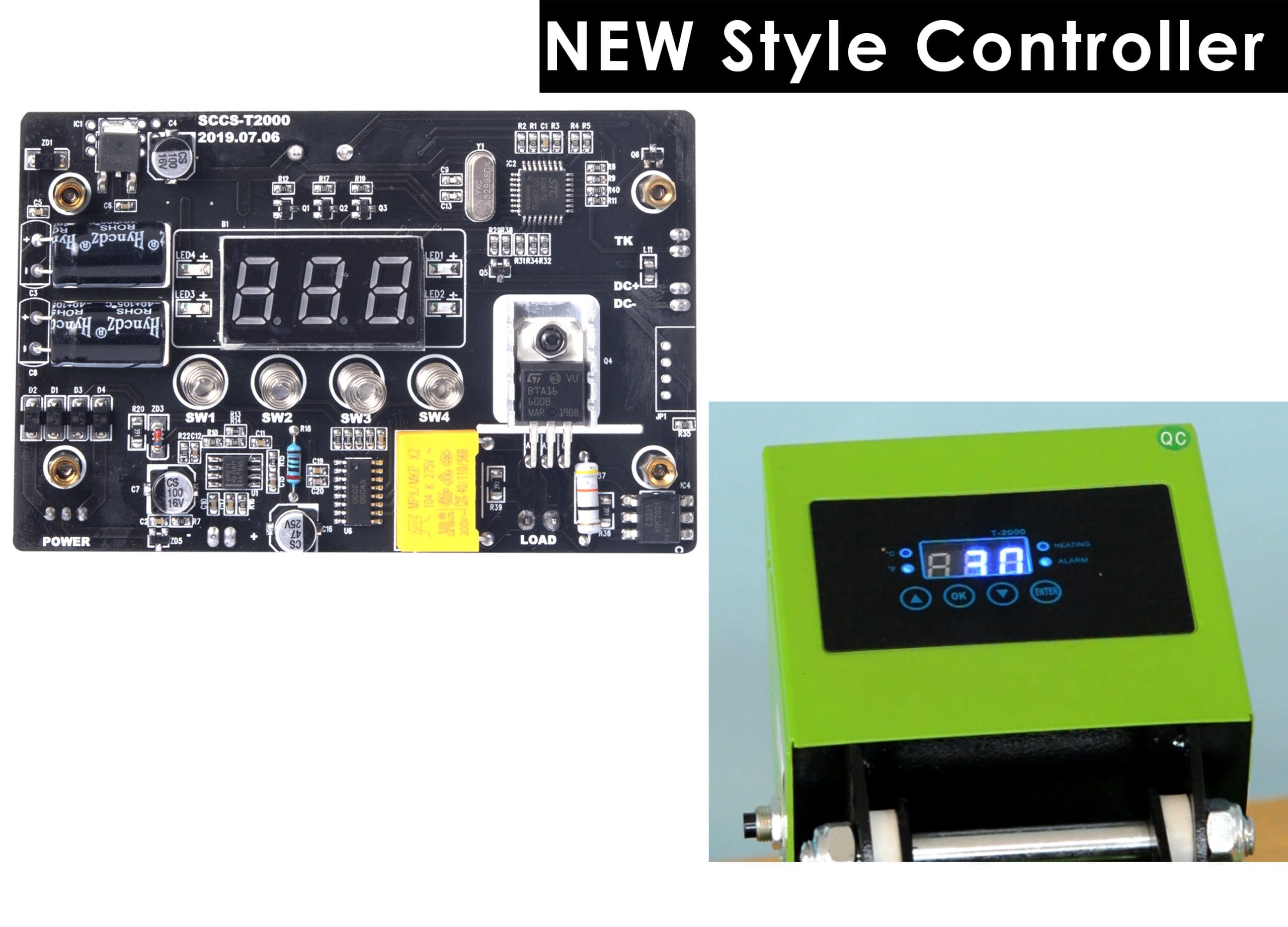

The Temperature Controller in Heat Presses

A temperature controller is essential for managing the heat in a press. It requires a temperature sensor to read the press’s temperature and a circuit to compare this reading to the user-selected temperature. The controller switches the heating element on and off to maintain the desired temperature, repeating this cycle continuously during use.

Temperature Sensor Placement:

- Mug Presses:

The sensor is embedded within the element. - Presses with Platens:

The sensor is usually bolted onto the heat element.

Evolution of Temperature Controllers

Standardization Era:

- Old Controllers:

Previously, heat presses used standardized controllers, sensors (thermocouples), and timers. This made repairs straightforward, as components were widely available off the shelf.

Customization Era:

- Custom Controllers:

Manufacturers began creating custom controllers to differentiate their products and reduce costs. This shift led to several issues for customers:- Replacement Challenges:

Custom controllers are not interchangeable with off-the-shelf models, making replacements difficult and often requiring parts from the original manufacturer. - Sensor Compatibility:

Non-standard sensors mean you can’t easily replace them with generic parts. - Integrated Components:

If any part of the custom controller fails, the entire unit often needs replacement. - Reliability Issues:

New digital controllers are generally less reliable than the old standardized ones. - Cost:

Custom controllers can be more expensive, as manufacturers can set higher prices.

- Replacement Challenges:

Understanding these aspects can help you make informed decisions about maintaining and repairing your heat press equipment.

Conclusion

As you can see, there’s more to a heat press than meets the eye. When selecting a heat press, consider the following factors:

- Volume and Size:

Choose a press that matches your intended volume and slightly larger than your initial needs. - Avoid Distractions:

Don’t be swayed by features like controller memory, press count, or auto-opening. Focus on the quality of the press. - Build Quality:

If a press looks poorly made, it likely is. It may work well for a while, but spare parts might be hard to find. - Aluminum Platen Thickness:

Thicker aluminum platens are better for heat consistency and durability. - Weight: Heavier presses are generally better. Light presses may not be as durable.

- Multifunction Presses:

Be wary of the number of accessories. A multifunction press that does caps, mugs, T-shirts, and plates is a 4-in-1 machine. Extra accessories don’t necessarily mean better quality. - Longevity:

Decide if you need a press that will last for a few years or decades. - Short-Term Use:

If you only need the press for a short-term job, consider buying the cheapest option and selling it second-hand or discarding it afterward.

Ultimately, the price and warranty offered by the supplier can indicate the quality of the press. A higher price and longer warranty usually mean better components and a supplier confident in their product.

Heat Presses We Sell At JG Electronics

If you would like to know more about the Heat Presses we sell at JG Electronics, you can follow this link to our information website.