Cart

Subtotal: R8044,25 (incl. VAT)

Choosing a heat press can be overwhelming with the many options available today. Heat presses come in all shapes, sizes, and colors, each with unique features and designs. From sleek and modern to industrial and functional, it can be hard to decide which one is best suited for your needs. In this blog, we aim to give you must-know heat press facts to help you navigate the various types of heat presses and select one that meets your budget and application requirements

No matter the size, color, or cost, all heat presses operate on the same basic principles as household appliances like irons and stoves. They feature a heating element, typically connected to mains voltage, which heats up and transfers warmth to an aluminum plate or rubber pad.

The desired temperature is set by the user, and once reached, the heat element turns off. When the temperature falls below a certain threshold, it reheats, repeating the cycle as needed.

Some presses are equipped with features like auto-open functions and digital temperature control, but the core process remains simple: heating an object for a designated time and temperature to achieve a specific transfer result. While most presses have one heated surface, some specialty presses, such as dual-sided T-shirt presses, offer two heated platens for faster, double-sided transfers.

Today, heat presses are available for a wide variety of applications, including:

Only T-shirt presses offer two distinct main types of mechanisms, each with some variations: clamshell and swing-away. Other types of presses generally come with just one mechanism option. In different regions, these mechanisms may have various names; for instance swing-away presses are known as 'swing' or 'shaking' presses.

If the mechanism appears fragile or has visible, defined welding marks, it’s likely a lower-quality press that isn’t intended for heavy-duty use. And if the mechanism is made of plastic, it’s considered the lowest end in terms of quality.

A clamshell press opens and closes at an angle, similar to a sandwich toaster or waffle maker. While it doesn’t open completely vertical, it usually stops at an angle of about 45 degrees.

Advantages:

Disadvantages:

In a swing-away press, the heat platen lifts vertically and then swings to the side.

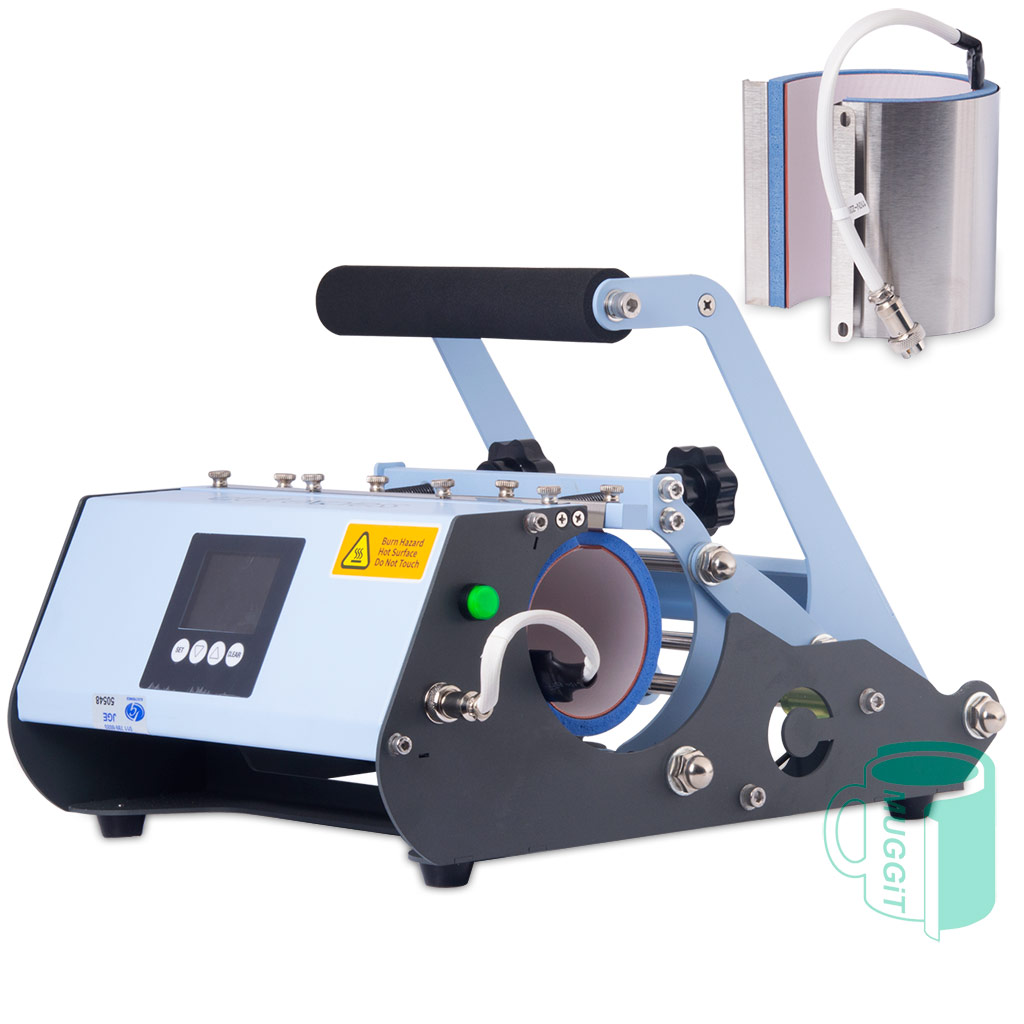

Combination presses are versatile units that, while primarily designed for pressing T-shirts, also come with a range of add-ons that connect to the main press controller. These attachments allow for pressing on various items like caps, mugs, plates, and even pens.

This type of press is ideal for beginners entering the business, as it provides the flexibility to work on multiple items without the need for separate, specialized presses. However, they aren’t built for handling high-volume production.

These days, both swing-away and clamshell presses often come with additional features such as an auto-release function, which uses an electromagnet to keep the press closed. When the timer reaches zero, the power is cut, releasing the magnet and allowing the press to open.

Other features, like pull-out drawers, are also available. While these add-ons may help differentiate products, they do not significantly improve the quality of the transfer and are often considered more of a marketing gimmick than a practical enhancement.

JG Electronics, with a background in manufacturing heat presses in South Africa during the 1990s, has gained unique insights into heat press construction. This experience has provided them with valuable knowledge of hidden details and nuances that many resellers have yet to uncover.

Heat elements require specialized wire, with Nichrome (a nickel-chromium alloy) being the most commonly used due to its high efficiency, durability, and ability to withstand temperatures up to 1150°C. For higher-end applications, Kanthal and Constantan wires are also used, offering greater stability and longevity.

While some low-end manufacturers may use copper or stainless steel wire to reduce costs, these materials require more energy to reach the same temperatures, ultimately leading to higher electricity costs for the user—offsetting any initial savings from purchasing the cheaper product.

Heat presses utilize various types of heat elements, each designed for specific applications:

Choosing the right heat element is crucial for achieving optimal performance and longevity in your heat press machine.

Users sometimes report cold spots on a press, mistakenly thinking the element has burnt out in certain areas. However, a heat element is essentially a long wire, and if it burns out or is cut in one place, the entire element will stop working.

Cold spots can occur due to:

If the element is too widely spaced within the heat platen, it can cause uneven heating.

Imperfections during the casting of the aluminum platen can also lead to cold spots.

Proper maintenance and quality control during manufacturing are essential to prevent these issues and ensure consistent heating performance.

While the methods JG Electronics used 30 years ago are still widely used today, many high-end manufacturers have significantly improved aluminum casting processes. These advancements reduce casting defects, making the finished product more expensive but also increasing heat consistency throughout the platen and dramatically improving the lifespan of the element. Here’s a brief overview:

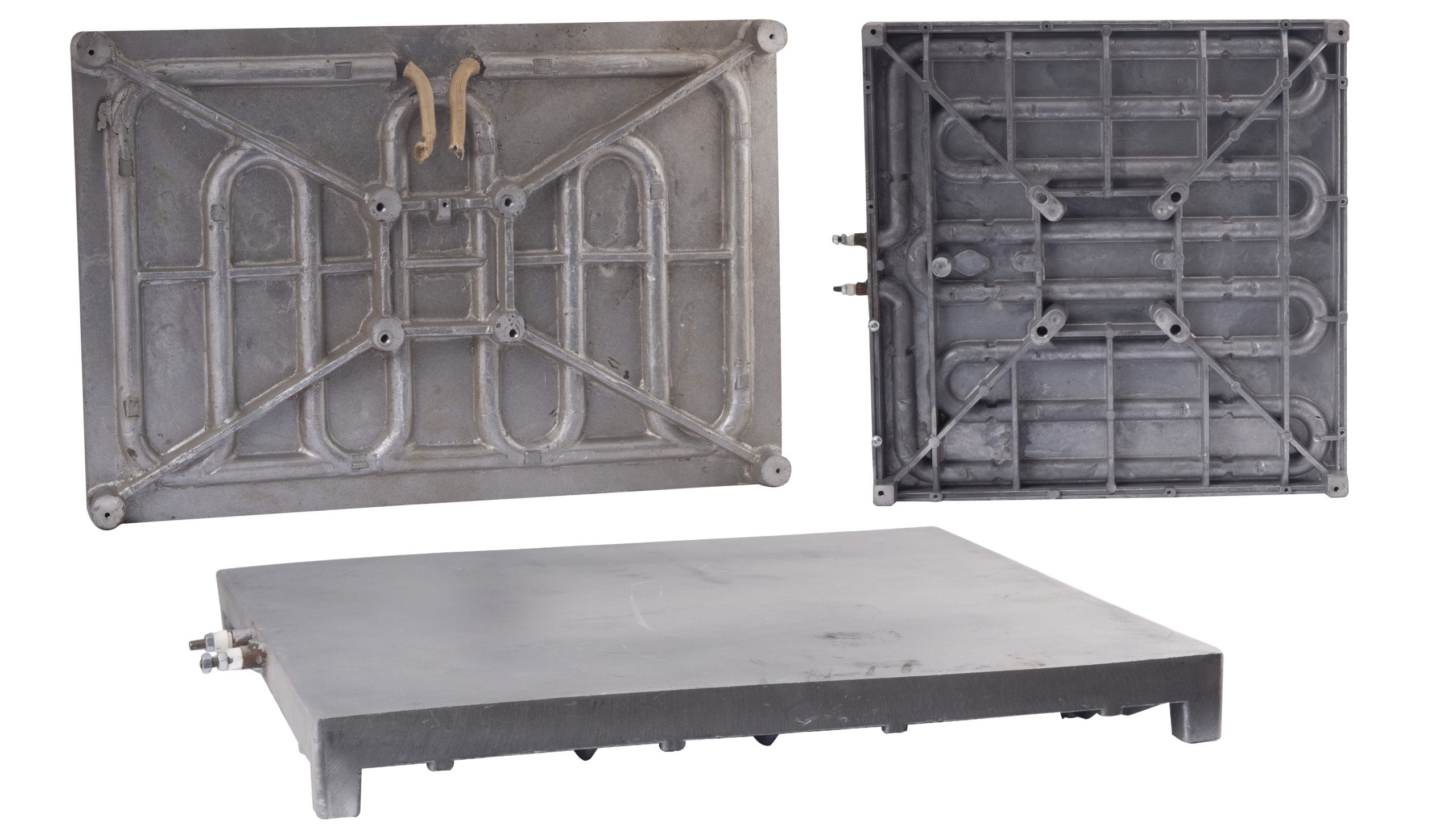

The heat platen is the metal block that the element is either:

Material: Aluminum is preferred for its excellent thermal properties and light weight. However, some cheap presses use metalized plastic heat platens, which don’t last long.

Function: The heat platen is heated by the element and transfers heat to the product being imprinted. Thicker aluminum platens are heavier and more expensive but less likely to warp, especially in larger presses. More professional casting processes result in more consistent heat distribution.

A balance must be struck between thermal conductivity and strength:

Thicker elements are better for strength. Thin elements use stronger, less heat-conductive aluminum, consuming more electricity.

Common in T-shirt and flat presses. Proper casting is crucial; defects can lead to poor heat dissipation and shorter element lifespan.

Example: Look for uneven or missing aluminum on old press elements.

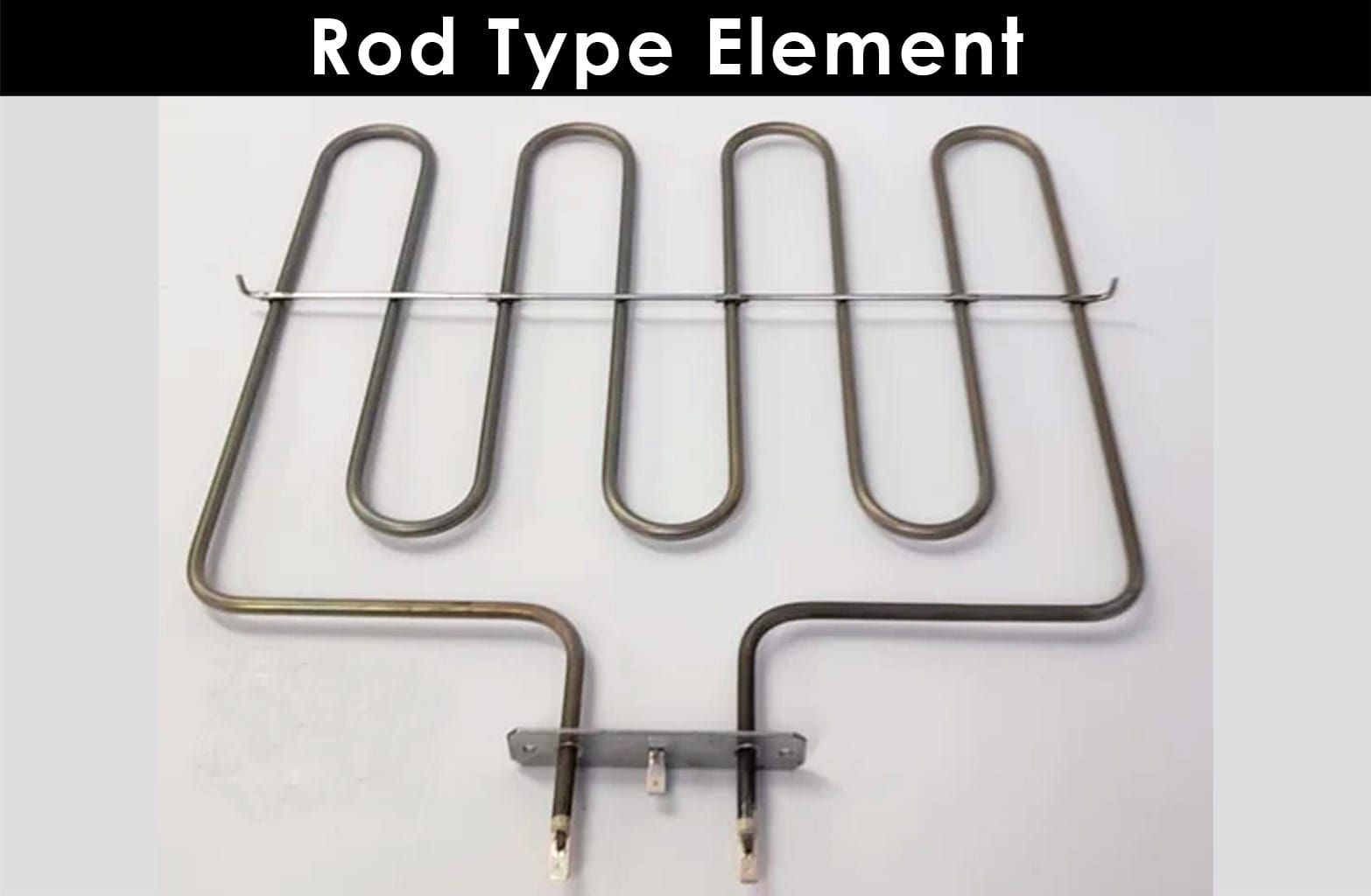

Oven Type Elements

Used in cheaper presses to save costs. These presses often have cold spots due to widely spaced element segments.

Example: Compare presses with oven elements (green tick) and Z/X elements (red crosses).

Z or X Shaped Elements

These improvements and considerations ensure better performance and longevity of heat press machines.

Most mug presses feature round nichrome heat element wire embedded in a flexible, heat-resistant silicone rubber pad, adhered to a heat-resistant foam moulding, often with Teflon on the side that contacts the item. These elements are common in the market and sometimes include a thin metal mounting plate glued to the back for easy installation.

Applications:

Important Note:

Advantage:

Disadvantage:

Proper usage and understanding of these elements can help extend the life of your mug press and ensure consistent performance.

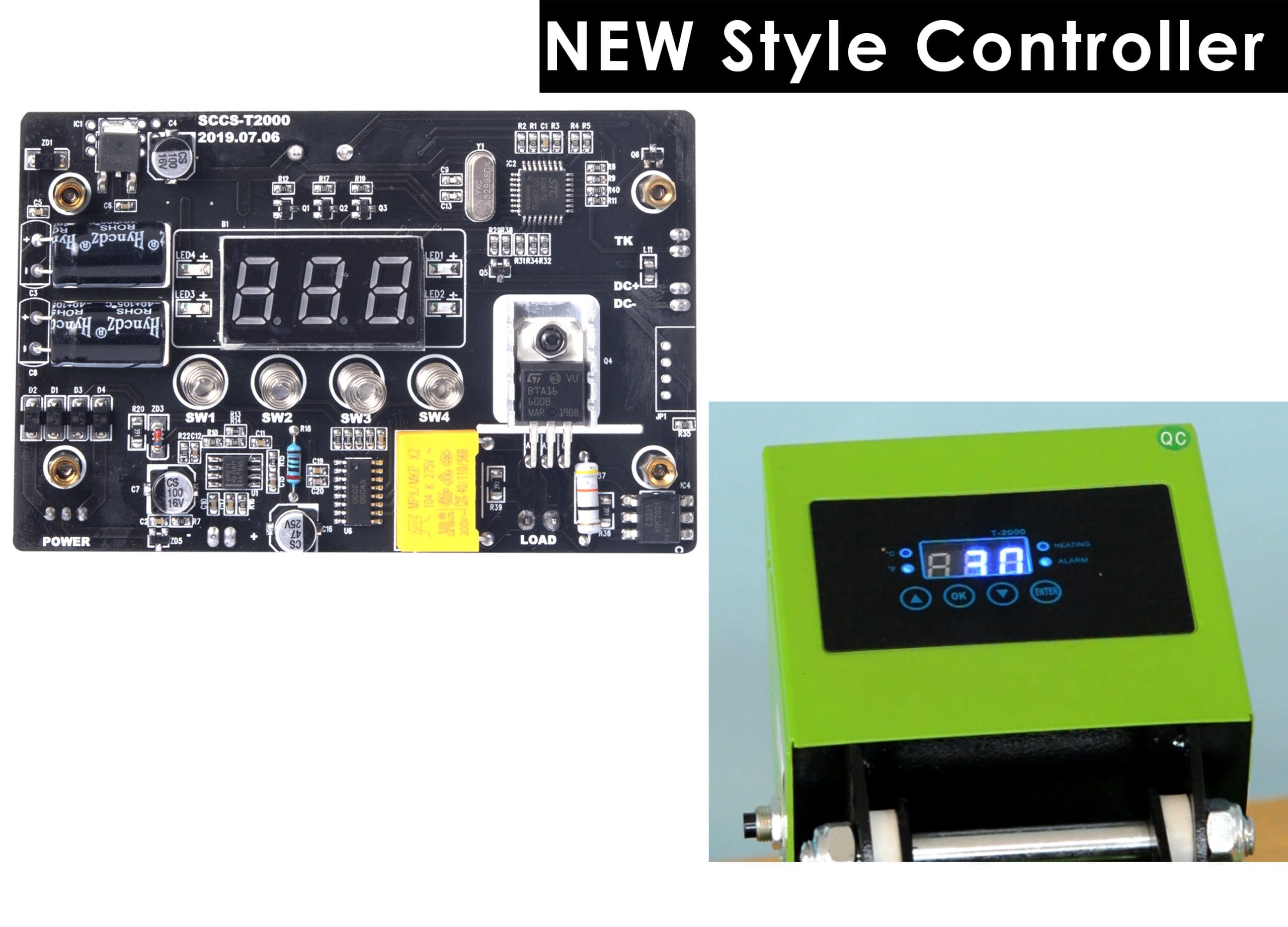

A temperature controller is essential for managing the heat in a press. It requires a temperature sensor to read the press’s temperature and a circuit to compare this reading to the user-selected temperature. The controller switches the heating element on and off to maintain the desired temperature, repeating this cycle continuously during use.

Temperature Sensor Placement:

Standardization Era:

Customization Era:

Understanding these aspects can help you make informed decisions about maintaining and repairing your heat press equipment.

As you can see, there’s more to a heat press than meets the eye. When selecting a heat press, consider the following factors:

Ultimately, the price and warranty offered by the supplier can indicate the quality of the press. A higher price and longer warranty usually mean better components and a supplier confident in their product.

If you would like to know more about the Heat Presses we sell at JG Electronics, you can follow this link to our information website.